Utilizing advanced composites like carbon fiber and aluminum alloys can drastically reduce vehicle mass, enhancing performance and handling. These components boost acceleration while maintaining structural integrity, providing both strength and agility.

Consider how the integration of titanium in exhaust systems optimizes weight while improving durability and sound quality. This choice not only elevates aesthetic appeal but also fine-tunes overall vehicular performance.

Innovative foams and polymers contribute to sound insulation and vibration absorption, creating an unparalleled driving experience. Manufacturers now leverage these lightweight elements to achieve a balance between elegance and functionality in their high-performance vehicles.

Employing such progressive choices enables engineers to push the limits of traditional crafting, resulting in breathtaking designs that attract enthusiasts and collectors alike. It’s a thrilling era for automobile artistry, driven by the pursuit of excellence through smart material selection.

Innovative Carbon Fiber Applications in Supercar Structures

Utilizing carbon fiber in the framework of supercars offers significant weight reduction and enhanced performance. Manufacturers are leveraging this composite for parts such as chassis, body panels, and suspension components to improve rigidity without sacrificing speed.

Integrating a carbon fiber monocoque not only lowers overall mass but also elevates safety standards. The structural integrity provided by this material allows for greater energy absorption during impacts.

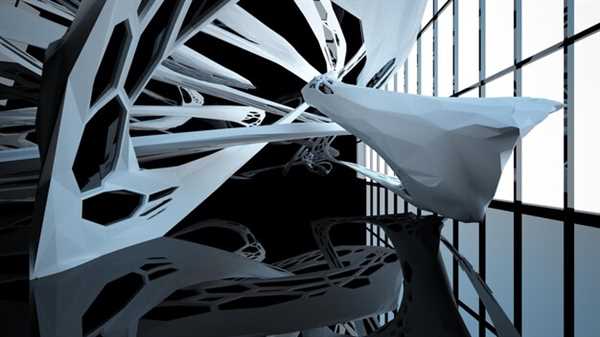

Advanced techniques like resin transfer molding enable the creation of complex shapes, enhancing aerodynamics. Supercars benefit from lower drag coefficients and improved handling due to these meticulously crafted designs.

Furthermore, the application of carbon fiber in interior components, such as dashboards and door panels, reduces weight while maintaining luxurious aesthetics. Manufacturers increasingly focus on decorative finishes, combining aesthetic appeal with structural benefits.

Real-time monitoring technologies can be incorporated into carbon fiber elements, allowing for enhanced data collection on performance metrics. This integration supports continual optimization of vehicle dynamics.

The Role of Magnesium Alloys in Enhancing Performance and Safety

Incorporating magnesium alloys into automotive engineering can significantly improve vehicle dynamics and occupant protection. These alloys exhibit remarkable strength-to-weight ratios, contributing to decreased mass and enhanced speed capabilities.

Key advantages include:

- Superior rigidity: Magnesium alloys possess an impressive structural integrity, allowing for robust frames that maintain safety standards during extreme conditions.

- Thermal conductivity: This characteristic aids in dissipating heat effectively, minimizing risks associated with overheating components during high-performance scenarios.

- Corrosion resistance: Advanced treatments enhance durability, ensuring that lightweight components withstand environmental stressors over time.

Implementing magnesium in critical areas, such as chassis and wheel structures, allows manufacturers to create agile yet secure models. Testing shows that vehicles utilizing these alloys can achieve improved acceleration and braking distances, which are crucial for high-speed performance.

In safety assessments, magnesium frameworks also contribute to energy absorption during impacts, reducing risks for drivers and passengers. The combination of lower weight and stronger materials leads to enhanced handling responsiveness, crucial for maintaining control in challenging driving conditions.

While magnesium alloys offer compelling benefits, engineers must also consider their fabrication challenges, such as processing techniques and cost implications. Addressing these factors is essential for integrating these advanced elements efficiently into high-performance machines.

Through strategic application, magnesium alloys stand out as a leading choice for those endeavoring to push boundaries in automotive excellence while prioritizing safety and performance metrics.

Assessing the Benefits of 3D Printing for Custom Lightweight Components

Utilizing 3D printing for tailored components offers significant advantages in performance and customization. This technology reduces production weight while maintaining structural integrity, essential in high-performance vehicles.

Precision capabilities enable the creation of intricate geometries. By optimizing designs, manufacturers can enhance aerodynamics and fuel efficiency, translating directly into superior speed and handling.

Rapid prototyping allows for swift iterations, facilitating fine-tuning of parts without the delays inherent in traditional methods. This agility is invaluable in competitive environments where innovation drives market advantage.

3D printing minimizes material waste, contributing to cost savings and environmental benefits. By using only the necessary amount of raw substance, manufacturers can decrease their overall footprint while improving margins.

Furthermore, customization options cater to individual preferences and specifications. Clients can request unique features, ensuring that each vehicle is distinctive and tailored to specific performance criteria.

Incorporating additive manufacturing accelerates time-to-market, allowing brands to respond quickly to changing consumer demands and technological advancements.

Overall, leveraging 3D printing for creating specialized lightweight components positions manufacturers to achieve superior performance and agility in a highly competitive field.